This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Innovation As part of its commitment to continuous innovation, the company collaborates in research and development initiatives with leading technology centres and universities associated with both the study and production of the minerals that are the subject of its projects. Some of the R&D&I projects in which it currently participates or has collaborated: Strategic Minerals Spain is part of the European H2020 Tarantula project, which seeks to recover critical raw materials from mining waste, using environmentally friendly, sustainable and low-cost metallurgical processes. The aim of this project is to develop new recovery methods for three metals of high technological interest: Tantalum (Ta), Niobium (Nb) and Wolfram (W), using a variety of novel technologies (bio-, hydro-, iono-, pyro- and electrometallurgical) to develop an efficient and environmentally friendly process. This project is funded by the European Commission’s Horizon 2020 programme. (Grant agreement ID: 821159). Project link: https://h2020-tarantula.eu/ The main objective of this project was the reclamation of Penouta Mine tailings as an alternative source of Niobium (Nb), Tantalum (Ta) and Tin (Sn), developing a novel pilot-scale technology for the recovery of these metals, through a combination of pyro- and hydrometallurgical techniques. This project, with file number RTC-2017-6629-5, has been funded by the Ministry of Economy, Industry and Competitiveness and the State Research Agency in the context of the Challenges-Collaboration call for proposals of the State Programme for Research, Development and Innovation Geared towards the Challenges of Society, in the framework of the State Plan for Scientific and Technical Research and Innovation 2013- 2016. The company joined this initiative as a collaborator, forming part of the Advisory Board and supplying material from the Penouta site. These studies made the following possible: (i) to chemically and mineralogically characterise the materials to feed the future mine, as well as the Tin (Sn)-Tantalum (Ta)-Niobium (Nb) metal concentrates; (ii) to carry out high intensity magnetic separation tests for the separation of Tin (Sn) and Tantalum (Ta)-Niobium (Nb); (iii) to carry out milling and concentration studies, which served to increase the performance of the process plant and energy savings compared to the previous configuration. This initiative was part of Strategic Minerals Europe’s general project to reclaim the tailings at the Penouta Mine. Consisting of the in-depth study of numerous samples from different drill holes in a strategic line across the entire deposit, from which a genetic model has been developed to explain the mineralisation of Tin (Sn), Tantalum (Ta) and Niobium (Nb). The aim of this study was to improve the quality of the cassiterite concentrate obtained after processing the ore from the Penouta mine. IK4-AZTERLAN is working on a study to define the theoretical possibilities of enriching the Niobium (Nb) and Tantalum (Ta) enriched waste using methods related to melting the material. In collaboration with CENIM (National Centre for Metallurgical Research), the classic route of carbothermal reduction of the concentrate was followed to separate the metallic Tin (Sn), concentrating Niobium (Nb) and Tantalum (Ta) in the slag and optimising this process on a laboratory scale. Once this has been achieved, semi-industrial-scale tests will be carried out to verify the results of the first phase. Innovation

R&D&I Projects

Tarantula Project (European Project H2020)

Coordinator: Tecnalia

Collaborative action of 16 partners from 7 different countries.

Duration: 2019-2022

Development of technologies to obtain tin, niobium and tantalum from mining waste (ESTANNIO). Project Challenges Collaboration

Sponsor: Strategic Minerals Europe

Place: Penouta Mine

Collaborators: CENIM (National Metallurgical Research Centre) and KROWN S.A.

Duration: 2018-2020

OptimOre Project (Horizon 2020)

Coordinator: Polytechnic University of Catalonia, collaborative action with 8 European partners.

Duration: 2014-2018

Petrographic, chemical, mineralogical and petrogenetic study of the tantalum, niobium and tin mineralisation of the Penouta Mine

Sponsor: Strategic Minerals Europe

Place: Penouta Mine

Collaborator: Research Group for Mineral Resources and Deposits of the Geology Department of the University of Salamanca.

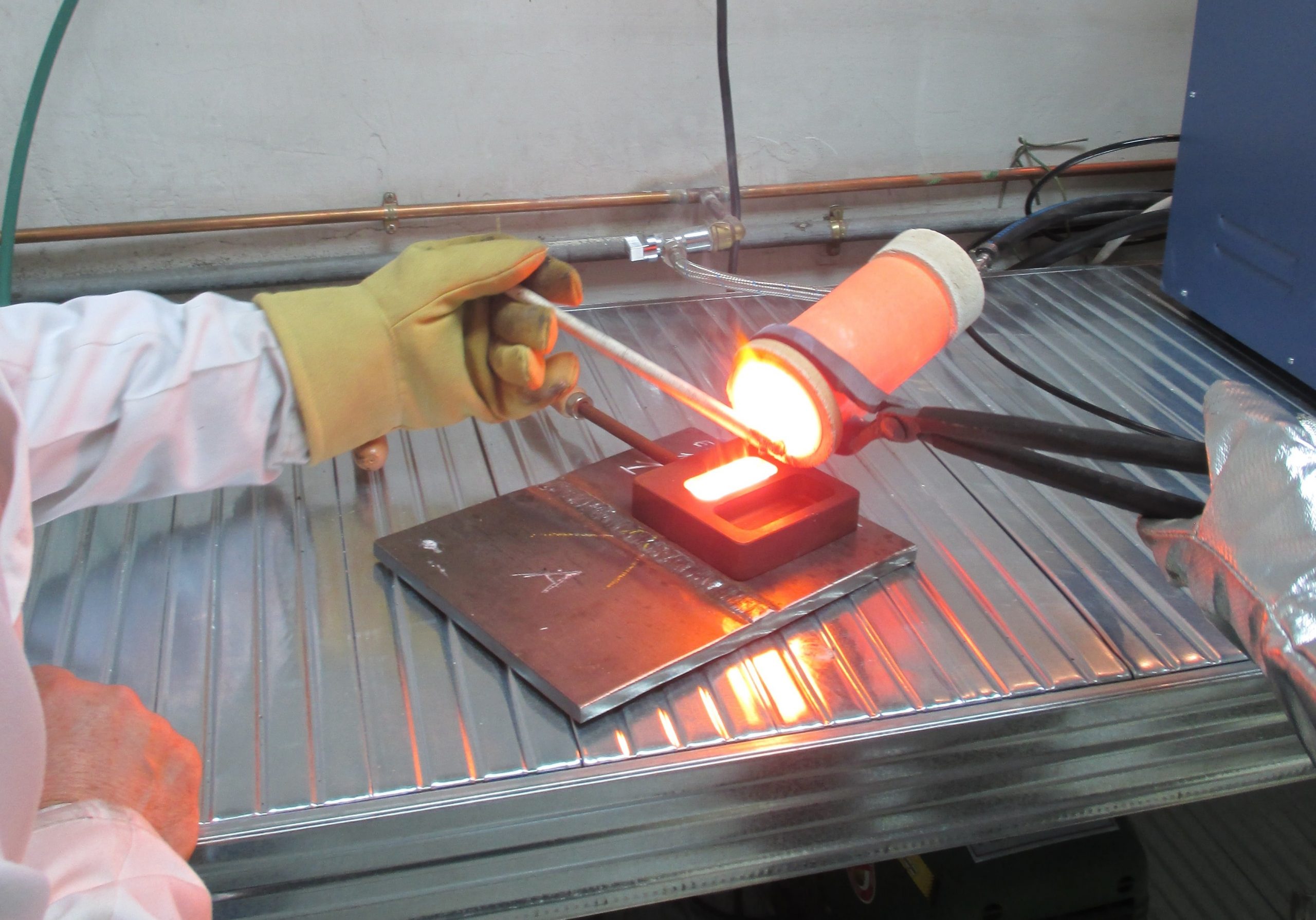

Smelting studies for Tin (Sn), Tantalum (Ta) and Niobium (Nb) concentrates

Sponsor: Strategic Minerals Europe

Place: Penouta Mine

Collaborators: AZTERLAN Metallurgical Research Centre and CENIM (National Metallurgical Research Centre)

R&D&I Publications